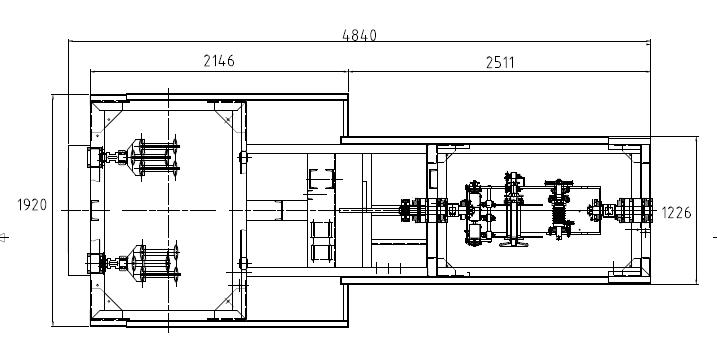

CNRM HDTM rope machine

CNRM HDTM combined strander and rope-layer

For production of finished coiled rope from natural and synthetic fiber yarns

Three-strand and four-strand models

From start to finish in one continuous operation

Extremely high output

Performance & advantages

· High productivity

· Sprocket drive

· Rigid construction

· Direct coiling head winding

· With digital length counter meter

· Auto stop after yarn breakage to control wastage

· Door sensor, protective door with steel wire mesh

· Low noise level, Low maintenance, easy operation system

· Surface of parts are bluing and with plating treatment

· Thermal refining for shaft parts, quenching treatment for gear and sprocket wheel

HDTM-M22

Technical data

Rope range: | Φ3-6mm | |

Lay range: | 18-30mm | |

Rope lay: | S or Z | |

Take-up, coiling head: | Φ480mm, traverse 265mm, barrel Φ138mm | |

Take-up, max. Weight: | Polypropylene 25kg | |

Pay-off packages | M22-3 | M22-4 |

3x3 , max.Φ175X300mm traverse | 4X3,max.Φ175X300 mm traverse | |

3x2 , max.Φ225X300mm traverse | 4X2,max.Φ225X300 mm traverse | |

Take-up capacity | Production capacity | |||

Coiling head | Output(kg/24hour) | |||

Φ3mm | 6250m | Φ3mm | 79kg | |

Φ4mm | 3572m | Φ4mm | 188kg | |

Φ5mm | 2500m | Φ5mm | 367kg | |

Φ6mm | 1563m | Φ6mm | 635kg | |

Examples based on three -strand polypropylene rope. Lay length: medium. Efficiency rate: 100%. 24 hour’s production

Motor-power: 1x 7.5kw AC HDTM-22-3/3 weight: 2400kg HDTM-22-4/3 weight: 2700 kg Height: 1.97 m

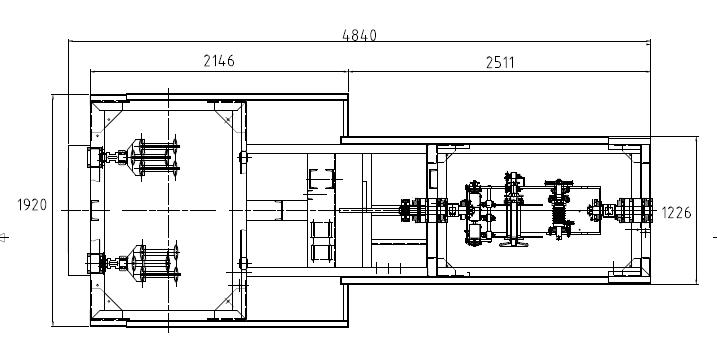

CNRM HDTM rope machine

CNRM HDTM combined strander and rope-layer

For production of finished coiled rope from natural and synthetic fiber yarns

Three-strand and four-strand models

From start to finish in one continuous operation

Extremely high output

Performance & advantages

· High productivity

· Sprocket drive

· Rigid construction

· Direct coiling head winding

· With digital length counter meter

· Auto stop after yarn breakage to control wastage

· Door sensor, protective door with steel wire mesh

· Low noise level, Low maintenance, easy operation system

· Surface of parts are bluing and with plating treatment

· Thermal refining for shaft parts, quenching treatment for gear and sprocket wheel

HDTM-M22

Technical data

Rope range: | Φ3-6mm | |

Lay range: | 18-30mm | |

Rope lay: | S or Z | |

Take-up, coiling head: | Φ480mm, traverse 265mm, barrel Φ138mm | |

Take-up, max. Weight: | Polypropylene 25kg | |

Pay-off packages | M22-3 | M22-4 |

3x3 , max.Φ175X300mm traverse | 4X3,max.Φ175X300 mm traverse | |

3x2 , max.Φ225X300mm traverse | 4X2,max.Φ225X300 mm traverse | |

Take-up capacity | Production capacity | |||

Coiling head | Output(kg/24hour) | |||

Φ3mm | 6250m | Φ3mm | 79kg | |

Φ4mm | 3572m | Φ4mm | 188kg | |

Φ5mm | 2500m | Φ5mm | 367kg | |

Φ6mm | 1563m | Φ6mm | 635kg | |

Examples based on three -strand polypropylene rope. Lay length: medium. Efficiency rate: 100%. 24 hour’s production

Motor-power: 1x 7.5kw AC HDTM-22-3/3 weight: 2400kg HDTM-22-4/3 weight: 2700 kg Height: 1.97 m